Author: Devika R

October 5, 2024

12 min read

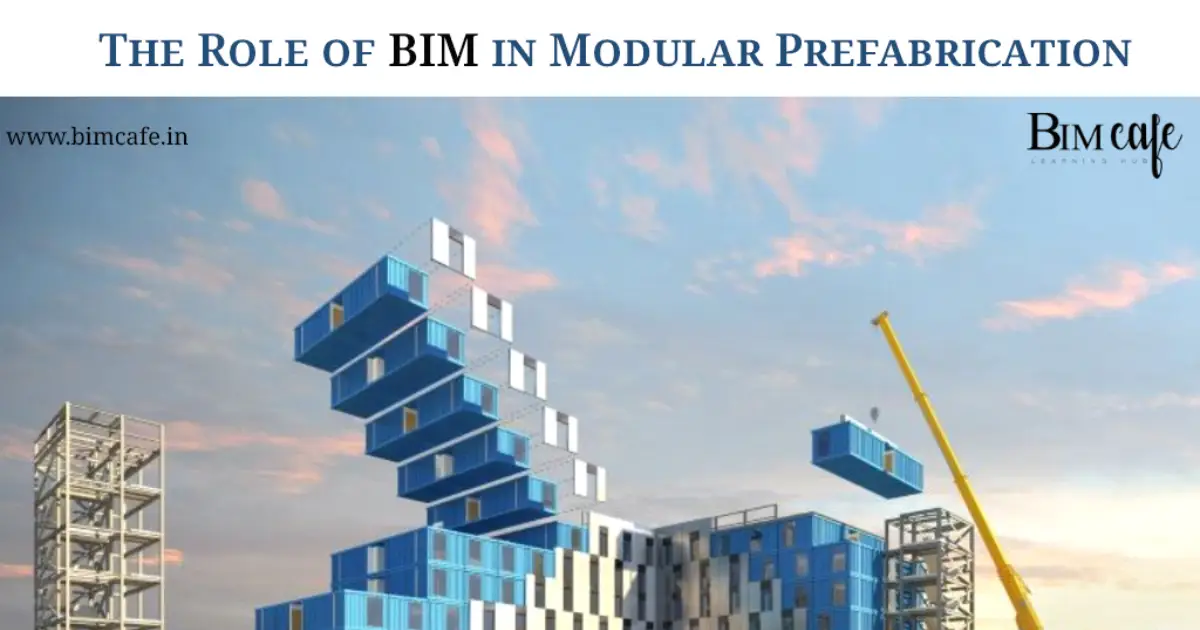

Modular Prefabrication: Building the Future, One Module at a Time

Imagine a construction site where buildings rise like puzzle pieces, fitting together with precision and speed. This is the reality of modular prefabrication, a revolutionary approach to construction that is transforming the industry.

What is Modular Prefabrication?

Modular prefabrication involves constructing building components or entire modules in a controlled factory environment and then transporting them to the construction site for assembly. These modules can range from simple wall panels to entire rooms or even complete buildings. This approach offers several advantages over traditional construction methods, including:

- Speed: Prefabrication significantly reduces construction time, as much of the work can be completed off-site, independent of weather conditions.

- Quality: Factory-controlled environments ensure consistent quality and reduce the risk of errors on-site.

- Cost-Effectiveness: Reduced labor costs, material waste, and project delays lead to overall cost savings.

- Sustainability: Prefabrication often involves less waste and fewer emissions compared to traditional construction.

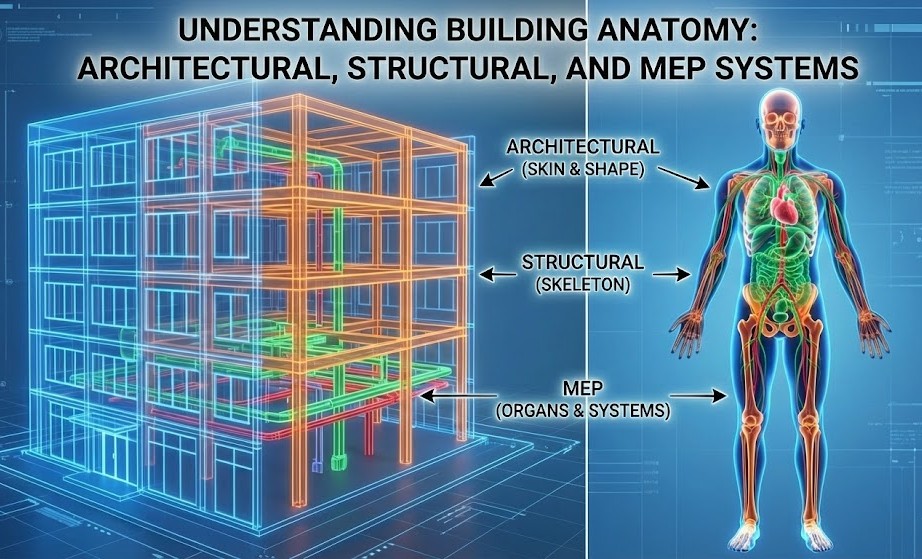

The Role of BIM in Modular Prefabrication

Building Information Modeling (BIM) has become an essential tool in modular prefabrication. BIM creates a digital twin of the building, allowing for:

- Enhanced Design and Coordination: BIM facilitates collaboration between architects, engineers, and fabricators, ensuring that all components fit together seamlessly.

- Detailed Shop Drawings: BIM can automatically generate accurate shop drawings for each prefabricated component, reducing errors and streamlining the fabrication process.

- Material Optimization: BIM helps optimize material usage by providing precise component information.

- Improved Quality Control: The digital model can be used to identify and address potential issues before they become problems on-site.

BIM-Driven Fabrication Methods

- Digital Fabrication: BIM can be integrated with digital fabrication technologies like 3D printing and CNC machining to create highly accurate and complex components. For example, BIM can be used to design and fabricate custom-made prefabricated wall panels with integrated electrical and plumbing systems.

- Automated Assembly: BIM-enabled robots and automated assembly systems can streamline the process of connecting prefabricated modules on-site. This reduces the risk of human error and improves efficiency.

- Virtual Reality (VR) and Augmented Reality (AR): VR and AR can be used to visualize and simulate the assembly process, allowing workers to practice and identify potential issues before construction begins.

Recent Developments in Modular Prefabrication

- Advancements in Technology: The construction industry is constantly evolving, with new technologies like 3D printing and robotics being integrated into modular prefabrication. These advancements are further improving efficiency and quality.

- Increased Adoption: Modular prefabrication is gaining popularity in various sectors, including healthcare, education, and commercial construction. As more projects adopt this method, we can expect to see even more innovative applications.

- Integration with Sustainable Practices: Modular prefabrication aligns well with sustainable construction principles. By reducing waste, minimizing site disruption, and using energy-efficient materials, modular projects can contribute to a greener built environment.

Challenges and Future Trends

While modular prefabrication offers numerous benefits, it also presents challenges such as transportation logistics, on-site assembly coordination, and potential disruptions due to unforeseen circumstances. However, ongoing advancements in technology and industry adoption are expected to address these challenges.

In the future, we can anticipate:

- Further integration of BIM and advanced manufacturing technologies.

- Increased standardization of prefabricated components.

- Expansion of modular prefabrication into new sectors and applications.

- Greater emphasis on sustainability and circular economy principles.

Modular prefabrication is a promising approach to building construction that offers numerous advantages. By leveraging BIM and emerging technologies, we can continue to push the boundaries of what is possible in the industry and create more sustainable, efficient, and high-quality buildings.

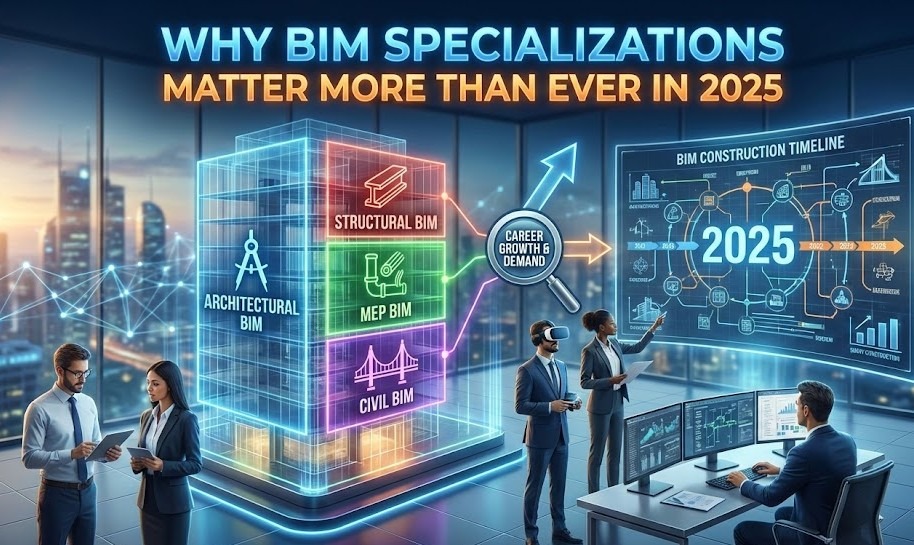

Why Learn BIM for Fabrication?

BIM has become an indispensable tool for professionals involved in fabrication. By learning BIM, you can:

- Improve Efficiency: BIM streamlines fabrication processes by providing accurate and up-to-date information.

- Enhance Collaboration: BIM facilitates collaboration between designers, engineers, and fabricators, ensuring that all parties are working from the same digital model.

- Reduce Errors: BIM helps identify and address potential issues early in the design phase, reducing errors and rework.

- Increase Productivity: BIM automation tools can streamline repetitive tasks, freeing up time for more complex and strategic work.

- Stay Competitive: As BIM becomes increasingly integrated into the construction industry, professionals with BIM skills will be in high demand.

Who Can Learn BIM for Fabrication?

BIM is relevant to a wide range of professionals involved in fabrication, including:

- Fabrication Engineers: BIM can be used to optimize fabrication processes, improve material usage, and reduce costs.

- Shop Floor Supervisors: BIM can provide real-time information on fabrication progress, helping supervisors manage resources and identify potential bottlenecks.

- Quality Control Inspectors: BIM can compare fabricated components against the digital model, ensuring they meet quality standards.

- Project Managers: BIM can help project managers track progress, manage costs, and identify potential risks.

Learning BIM for Fabrication at BIM Cafe Learning Hub

BIM Cafe Learning Hub offers a comprehensive range of BIM courses and training programs tailored to the needs of fabrication professionals. Their courses cover topics such as:

- BIM Fundamentals: Introduction to BIM concepts and workflows.

- for Fabrication: Specific applications of BIM in fabrication, including shop drawing generation, clash detection, and material optimization.

- Advanced BIM Techniques: In-depth training on advanced BIM features and tools.

- BIM Project Management: Learn how to use BIM to manage fabrication projects effectively.

By enrolling in BIM Cafe Learning Hub’s courses, you can gain the skills and knowledge needed to excel in BIM-driven fabrication.